Multi parameter, modular, single platform monitoring system for large motors and generators

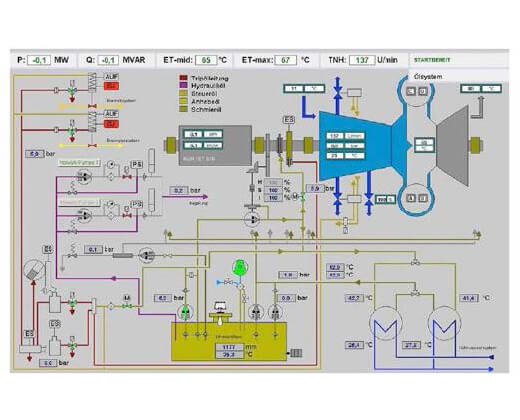

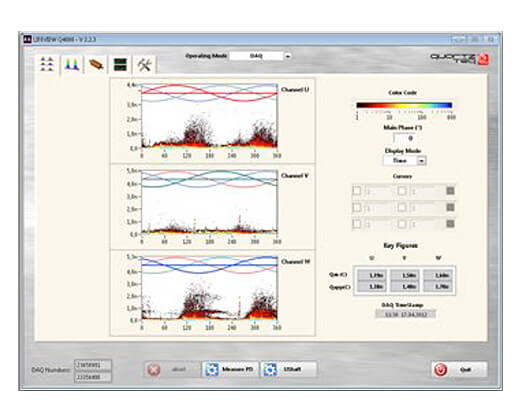

The single platform monitoring system acquires and evaluates multiple parameters related to the most prominent causes of degradation, thus preventing major failures.

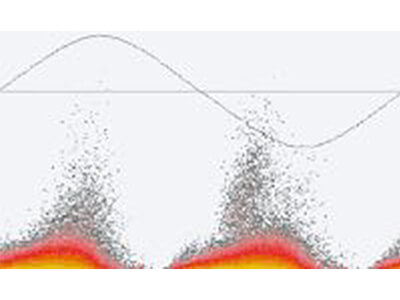

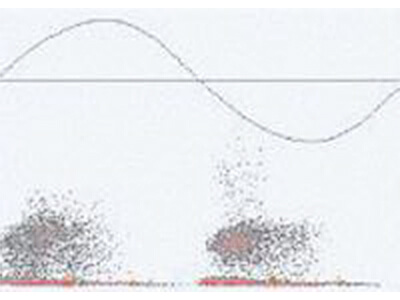

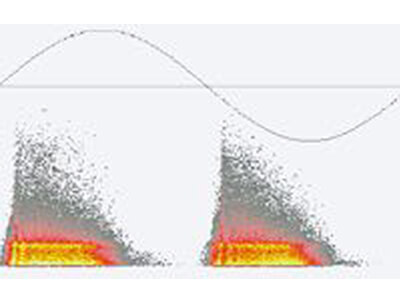

With wear and tear on high voltage rotating machines inevitable – caused through electrical and mechanical stress as well as the environment in which it operates – monitoring of the rotor and stator insulation systems can provide an early indication of the onset of detrimental risk factors that if not corrected through preventive maintenance, can lead to expensive unplanned outages.

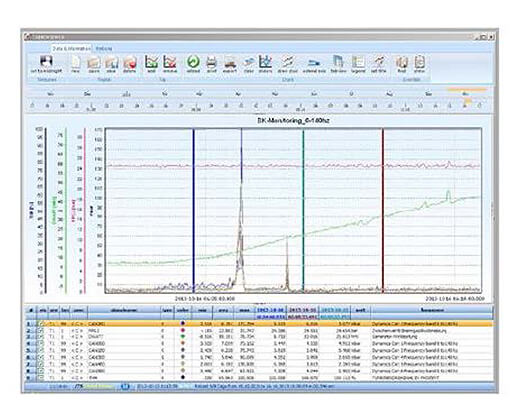

Detection of machine issues at an early stage can be achieved by multi-parameter monitoring allowing early remedial action. Over time, a condition-based approach proves cost effective with the reduction in needless, premature maintenance.

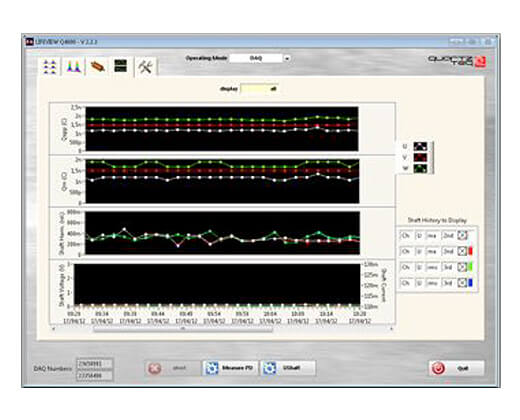

Highly modular, a wealth of functions can be added to the monitoring systems‘ main data acquisition unit, which is at the same time the gateway to a distributed smart wireless vibration and temperature sensor network, extending the functionality not only in area covered (less cables, energy harvesting), but also in number of possible data acquisition channels.

The main data acquisition unit provides sufficient computing power and storage, communicating with a cloud server, allowing remote expert access anytime, anywhere.

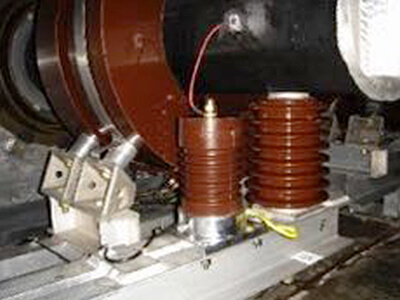

Historically, individual systems would have been used; now an integrated solution offers a single platform for monitoring the motor/generators‘ global condition as well as; rotor, stator, bearing and structural condition with the integration of mechanical components (e.g. gearbox, pump, turbine, compressor) currently in development which will ultimately create a global monitoring solution.

Our contribution will discuss the architecture of the system as well as its application on large turbine generators, HV motors and some mechanical elements.